Aging test

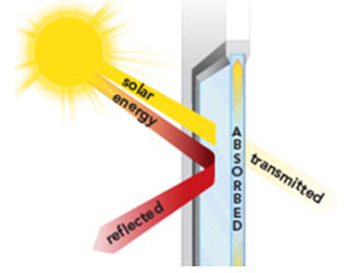

UV aging tests are designed to simulate the prolonged sunlight exposure that products may experience during normal storage conditions. In such tests, ultraviolet light—emitted by specialized equipment—is used as a substitute for natural sunlight, enabling the replication of long-term solar radiation effects within a compressed timeframe. The primary objective of UV aging tests is to induce and evaluate potential visual and physical changes in products under laboratory conditions. Ultraviolet rays refer to the invisible, specific wavelength range within sunlight that drives these accelerated aging processes.

Related ProductsIn advanced laboratories, UV aging chambers are utilized to simulate natural environmental conditions, measuring the detrimental effects of sunlight, moisture, and temperature on various materials—such as fading, cracking, peeling, oxidation, and similar degradation phenomena. Such chambers enable the shortening of testing time compared to real-world exposure.

During testing, parameters including temperature, humidity, and UV intensity are precisely controlled to replicate natural environmental conditions. This allows a wide range of materials—including paints, coatings, plastics, wood products, adhesives, and others—to undergo UV aging testing.

Our organization offers UV aging test services as part of its specialized testing service portfolio. These services support enterprises in efficiently, safely, and continuously developing high-performance, high-quality products with enhanced reliability. UV aging test services, provided under specialized testing offerings, represent just one of the multiple professional testing solutions available through our organization. A diverse range of additional specialized testing services are also offered to meet varied industry needs.