Food and Beverage

The use of UV light in sanitizing systems is a popular choice for destroying foodborne illnesses, diseases and other microbes that, while perhaps not dangerous, can cause food to spoil quickly, such as yeast and mold spores.

UV solutions have many advantages over other methods:

1. It uses no added chemicals or preservatives

2. It leaves no residue

3. The food will not be damaged or changed by the heat treatment process.

UV-C light has been proven to reduce or eliminate E. coli, Salmonella, Listeria and other foodborne, pathogens.

Examples of UV lamps used for disinfection in food and beverage production include:

UV lamps can be used as part of the disinfection process to treat surfaces, equipment and the air in food processing and packaging plants.

1. Use UV-treated water to grow fruits, vegetables and salads to avoid disease-spreading and food-damaging microbes in the crops.

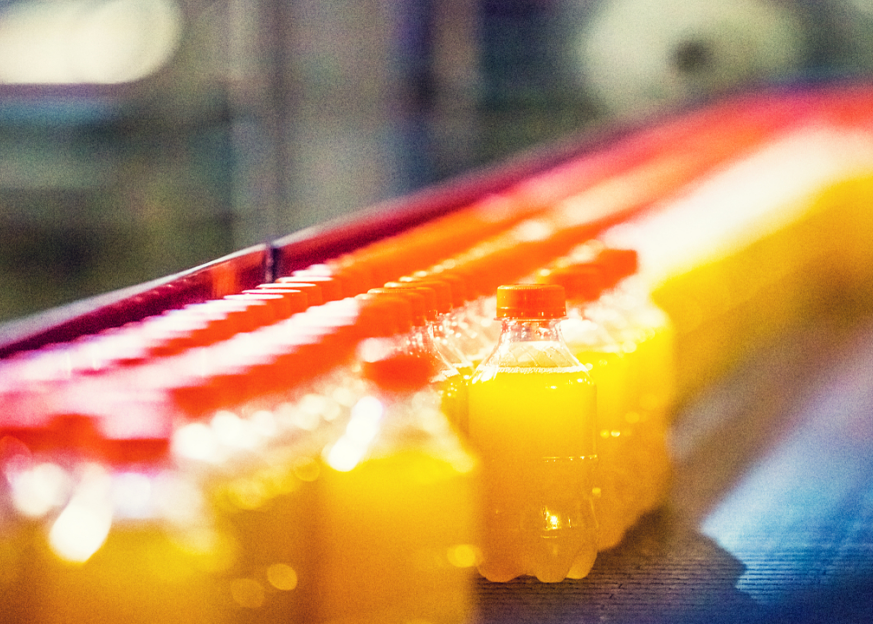

2. Fruit juices and ciders may undergo chemical changes if they are pasteurized using conventional heat methods, affecting the taste of the final product. After pasteurization of juice and cider using UV lamps, the product tasted as expected by the producer.

3. Milk pasteurization and raw milk product processing instead of heat treatment and chemical additives.

4. Syrups used in beverage production may contain a large number of dormant microbial spores. Treating water and syrups with UV light will help kill off any microbes.

5. Disinfection of food surfaces before packaging – products pass through a UV disinfection tunnel before processing and packaging to control microbial load.