Plastic and Rubber

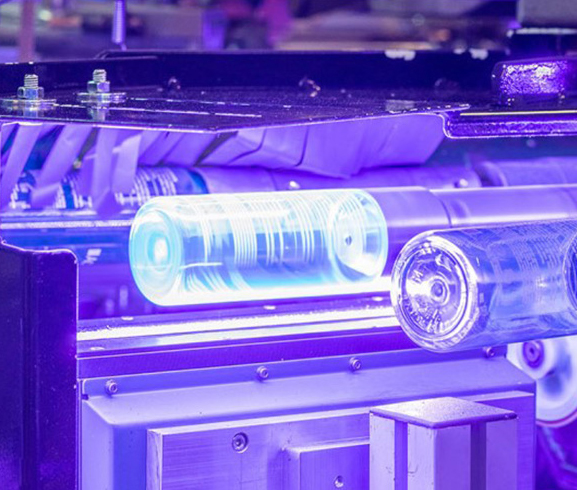

UV Curing of Plastic Decorative Coatings

Manufacturers of a wide variety of plastic products use UV curing to increase productivity and enhance the aesthetics and durability of their products Plastic products are decorated and coated with UV-curable inks and coatings to improve their appearance and performance. Plastic parts are often pretreated to improve adhesion of UV inks or coatings. UV decorative inks are usually screen printed, inkjet printed, pad printed or offset printed, followed by UV curing. Most UV-curable coatings, typically clear coatings that provide chemical and scratch resistance, lubricity, soft-touch, or other properties, are sprayed on and then UV-cured. UV curing equipment is built into or retrofitted into automated coating and decorating machinery, often as a step in a high-volume production line.

Related Products

Drying and curing using infrared heat

Depending on the paint system, infrared radiation can penetrate more or less into the interior of the material and dry the paint film from the inside out. Not only does it avoid surface peeling or blistering, but it also speeds up the paint drying process. The finished product has a shiny surface quality. The paint system can predefine frame data. Application example:

• Water soluble paint on bumper

• Airbag fabric

• Standoffs and switches

• Protective paint on the keyboard

• Ink

Advantages of UV curing

Improve product quality and durability

Improve productivity

Flexible painting and decoration of heat-sensitive plastics

without damage

Reduced footprint

Environmentally friendly as no VOCs and less energy

Advantages of infrared

Certain plastic parts cannot withstand heat for long.

A large amount of energy is transmitted to the part to be heated in a short period of time.

The temperature of the equipment, environment and other parts of the product will not be increased due to this.

Application

• Welding of plastic parts

• Heating of prepreg composites

• plastic packaging

• Infrared preheating of PET (blow molding machines)

• Shrinkage and stretching of plastic films

• Thermoforming

• Trimming printing / printing processing

• dry plastic pellets

• Crystallization and drying of PET, PPS, PLA

• Cures ink on plastic

• softening/bending

• vulcanization in the rubber industry

• Plastic tube stretching

• Sealing/bonding