printing industry

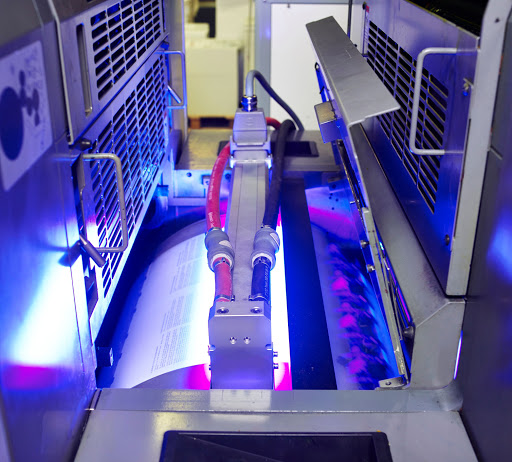

UV light for paper printing

UV printing has covered offset printing, screen printing, inkjet, pad printing and other fields. UV generally refers to the printing effect process in the traditional printing industry, which is to wrap a layer of varnish on a printed pattern you want (with Bright, matte, inlaid crystals, glitter powder, etc.), mainly to increase the brightness and artistic effect of the product, protect the surface of the product, its hardness is high, corrosion resistance and friction, and it is not easy to scratch, etc. Some laminating products are now changed to UV , can meet environmental protection requirements, but UV products are not easy to bond, and some can only be solved by local UV or grinding.

Related Products

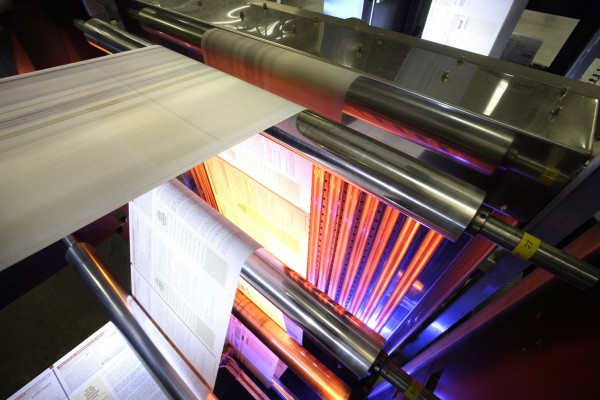

Infrared lamps for drying and digital printing

Save energy, space and time during the printing process Flexo napkins, offset brochures, screen-printed advertising material or automotive glass – print on a variety of materials. In digital printing, the ink must be dried as quickly as possible in order to adhere to the printing process. The Heraeus carbon infrared system (CIR) is particularly effective when processing water-based pigments, where the full output of the high-speed printheads can be fully utilized. Hybrid infrared emitters dry from the outside in.

Related ProductsAdvantages of UV curing

Faster switchover and shorter lead times

Improve productivity

Improve printing consistency

Improves durability, scratch and chemical resistance

Environmentally friendly, no VOCs

save energy costs

Ability to print on non-porous and heat-sensitive

substrates, broadening the range of applications

Advantages of Infrared

Contactless Energy Transfer

low maintenance

Infrared emitters precisely matched to the product

Optimal wavelength for faster drying and energy efficiency

Application

Lottery and Scratch Cards

Flexible Food Packaging

Paper and Cardboard Packaging

Direct mail, brochures, magazines and newspapers

Securities Documents and Currencies

Banner banners, bus advertisements

Labels - Pressure Sensitive & Shrink Sleeves, Holographic