Wood Industry

Drying and curing wood coatings using UV technology

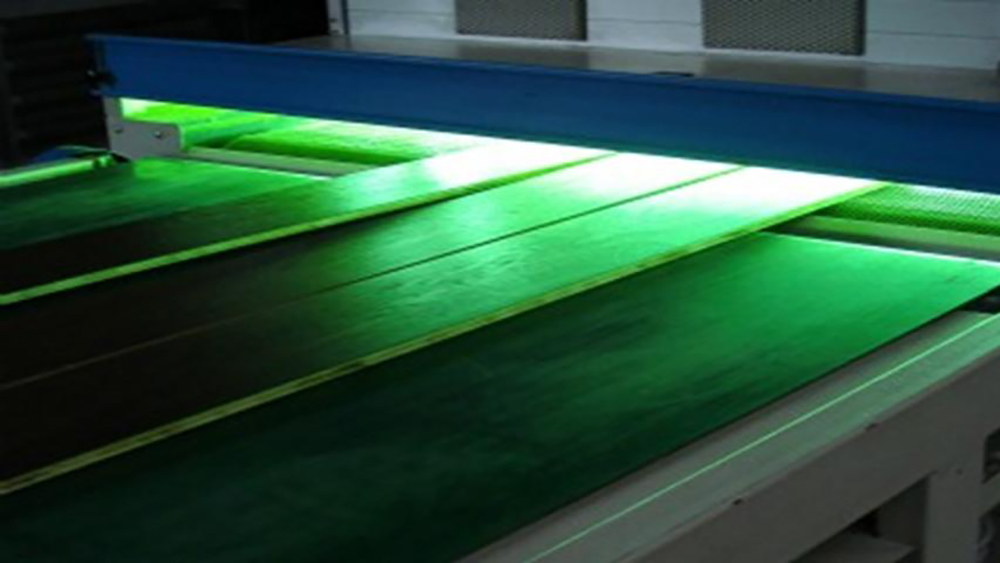

Wood product manufacturers use UV curing to increase productivity, improve product quality, and more. UV curing of fillers, stains, sealants and topcoats (both clear and tinted) is used by manufacturers of various wood products such as prefinished floors, battens, panels, doors, cabinets, particle boards , MDF and pre-assembled furniture. UV curing is a low-temperature curing process that significantly reduces process times while achieving long durability based on its high resistance to abrasion, chemicals and stains. UV coatings are low VOC, water-based or 100% solids and can be rolled, curtain coated, vacuum applied or sprayed onto wood.

Related Products

Infrared Technology for Furniture and Woodworking

In order for high-quality wooden furniture or precious parquet floors to remain attractive for a long time, their surfaces need to be carefully prepared and sealed. The infrared heating process is effective and does not damage the wood. Infrared heat for wood processing Wood processing benefits from infrared technology in several ways. Infrared radiation transfers energy into heat-generating materials without contacting the material, which makes it particularly effective for drying paint or primers, melting powder coatings or removing residual moisture without damaging the wood. In this way, the quality is improved and further processing of the wood can start much faster.

Related ProductsAdvantages of UV curing

Improve productivity

shorten the lead time

Reduce labor costs

Significantly reduce or completely eliminate VOCs

Higher quality processed products

reduce waste

Reduced footprint required for processing

Immediate operation and packaging

Reduced flammability reduces insurance premiums

Advantages of Infrared

Infrared emitters optimize the powder coating of fibreboards

Targeted heating improves lamination embossing lines

Infrared heat improves particleboard quality

Adhesive drying

Drying of wood stains

Gelling and Curing Wood

Application

Prepared hardwood floors (parquet and strips)

Beading and Trimming

Cupboards and Bathroom Cabinets

Wooden office and residential furniture

Particleboard and MDF panels and components