UV photochemical reaction

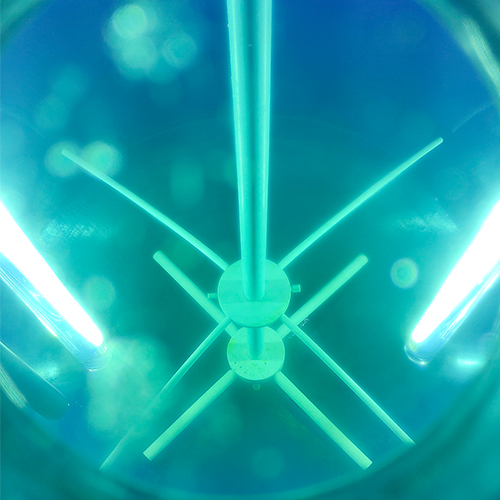

UV light modules are enclosed in quartz glass protection tubes, which are inserted into the equipment through nozzles at the top of the vessel. These tubes are also connected to the power supply and cooling system. The power range of such UV immersion lamps is 5-60 kW; therefore, internal cooling of the glass tubes is required to prevent damage to sensitive molecules caused by high surface temperatures. Industrial reactors are typically equipped with 4 to 20 such glass tubes, and the glass tubes with light sources must withstand both hydraulic and thermal loads within the stirred vessel.

Related ProductsTo achieve rapid reactions and thus improve production efficiency, a large number of chemical reactions need to be carried out at temperatures between 100 and 250°C. However, within this temperature range, substances are prone to decomposition reactions, leading to reduced yields and the formation of undesired by-products. Reactions can be initiated at lower temperatures with the help of catalysts, but the procurement and operational costs of catalysts are relatively high. Photochemical technology provides an efficient alternative for this purpose and supports new synthesis pathways. This technology does not rely on thermal energy or catalysts; instead, it activates reactions through light energy, enabling reactions to proceed at temperatures well below 100°C (often at room temperature). Through this method, decomposition reactions and by-products can be minimized or even completely avoided. The technical principle of using light instead of heat can be widely applied to various synthesis reactions such as chlorination, sulfonation, sulfoxidation, and nitrosylation.