Drug decomposition and synthesis

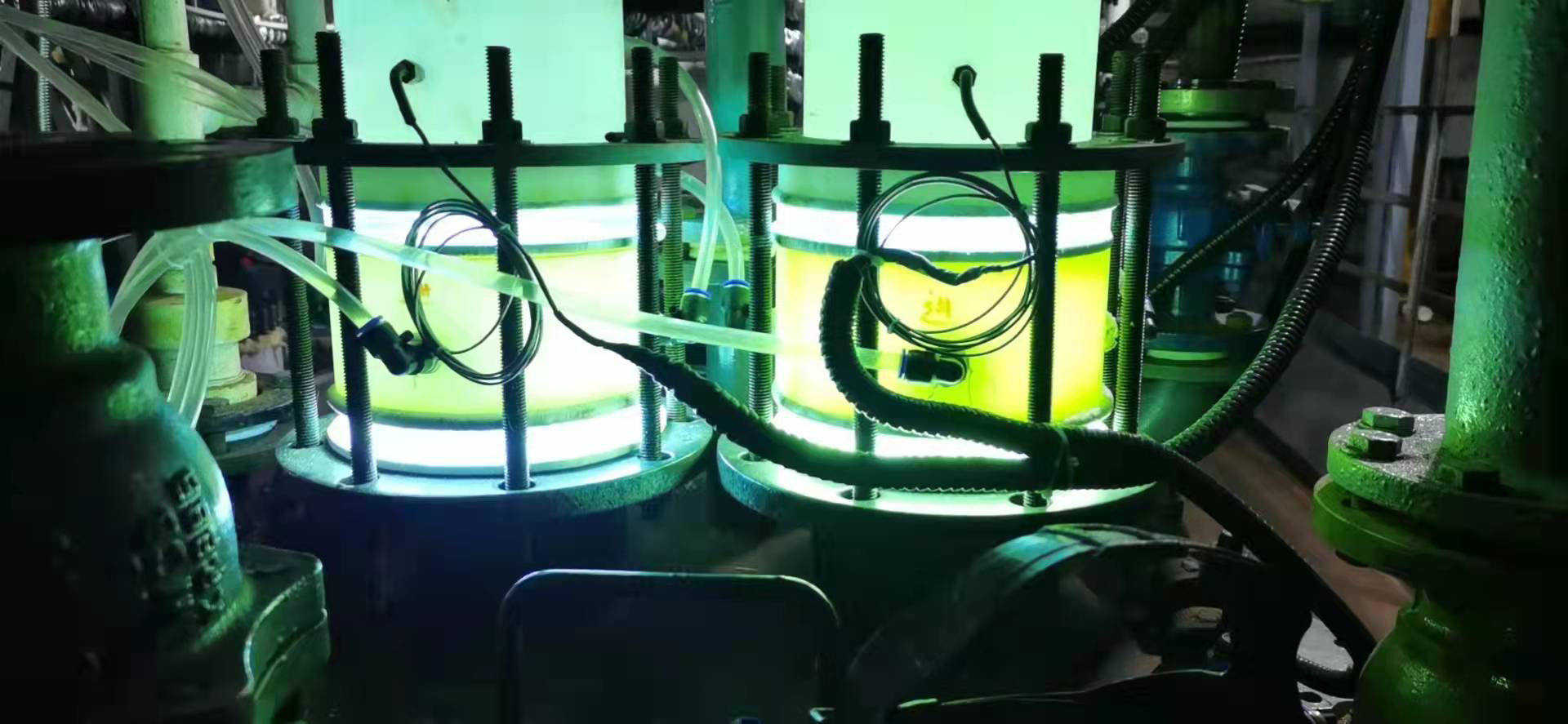

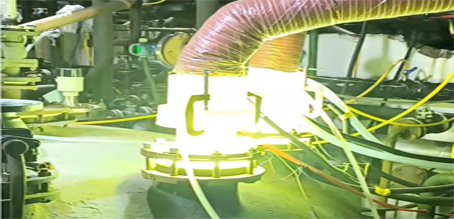

Manufacturers of high-quality organic compounds utilize UV systems to implement photochemical steps in organic synthesis. In this process, valuable components such as vitamins, hormones, and fragrances are produced through light-driven synthesis (preparative photochemistry).

Related ProductsPhotochemical systems are typically applied in the following applications:

Photochlorination / Sulfochlorination / Photonitrosation / Photoaddition / Photobromination / Photopolymerisation / Photodimerisation / Ring-chain valence isomerisation

Photochemical synthesis offers the advantage of shortening complex synthesis steps, thereby achieving high yields and high purity. In many preparative photoreactions, high purity is attributed to moderate reaction conditions, as thermal side reactions are effectively suppressed. Additionally, photochemistry enables numerous reactions to be performed at very low medium temperatures.

UV systems composed of modular assemblies offer extensive flexibility in material selection and combinations. This includes reactor housings (such as quartz glass or stainless steel of various grades) and sealing materials (a wide range of polymers). It is even feasible to integrate glass bodies with stainless steel end caps. When required, each seal can be pressurized using a high-pressure sealing medium, enabling applications in the food sector, pharmaceutical industry, and medical technology.